LEAP Management

Power users and Administrators have access to most of Qlector LEAP settings, so most of management can be done in-house. They will also be able to access some additional overviews and reports.

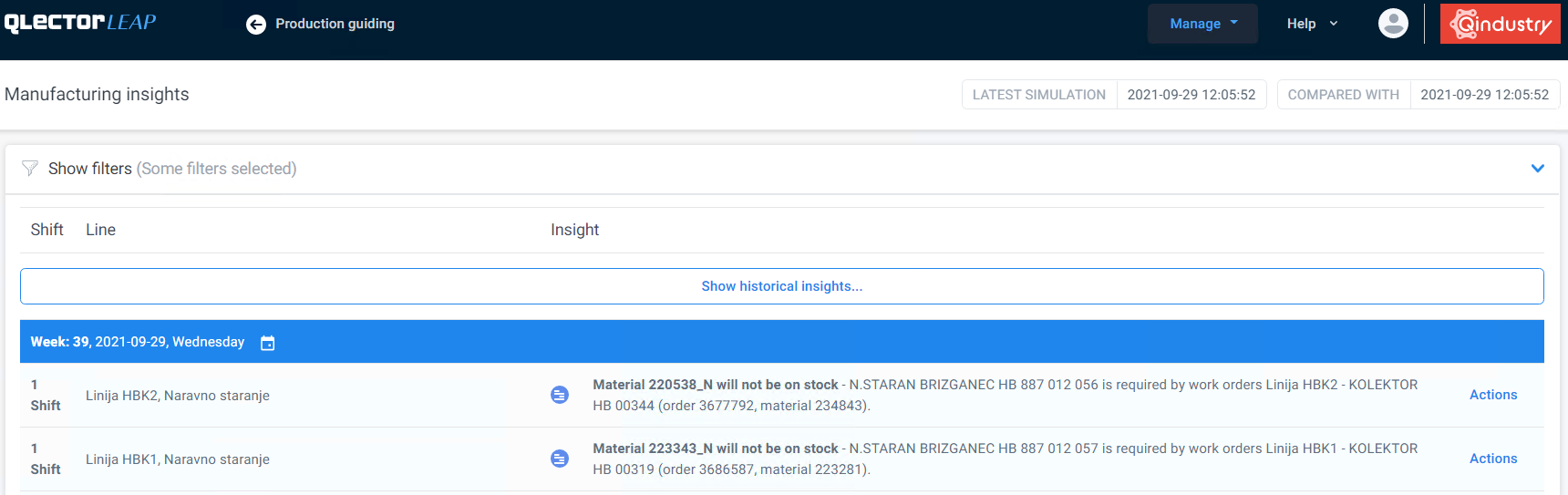

Insights

All insights are shown here, and additional filters can be applied:

Resources

This section includes the necessary settings for LEAP configuration. Tags are used to control parameters, although some are not meant to be changed.

- Plants

- Line-groups

- Lines

- Batchop-groups

- Batchop-locations

- Stock locations

- Materials

- Processes

- People

The settings in each tab are explained in detail in following subsections.

Plants

All plants are listed on the left. Selecting a plant shows details on the right.

- Plant: Plant name

- External ID: ID of the plant from ERP

- Weight: order position of the plant in lists

- Tags: line settings parameters and their values

- Lines: A list of lines in this plant. Clicking on a row redirects to Lines tab (see 2.2 Lines)

- Line-groups: A list of line-groups in this plant

| calendar_plant | 21 characters long numerical string, each number represents shift of the week | 21 characters long numerical string, each number represents shift of the week. 1=open shift, 0=closed shift) |

| contact_person | Contact person | Contact person for the plant visible on ‘Help’ menu |

| contact_person_email | Contact person’s e-mail address | Contact person’s e-mail address used for ‘mailto’ link on contact person’s menu item |

| enable_tool_transfer_print | Enable tool transfer printing | Enable printing of tool transfer document from Tools/list of tool changes/Actions |

| has_multiple_machines | Has multiple machines | Indicates whether the plant has work-centers with multiple machines. When turned on, machine_assignment task provides machine assignment data for the plant. It will get data from MES and use historical data to assign an operation to specific machine. If no history is available, default machine is used. If turned off, individual lines can still be defined as multiple_machine, but historical data will not be used for scheduling. |

| ignore_material_tags | Ignore material tags | Ignore materials with the tags in the plant. For example: OROD, VERP, LEICH |

| insight_freeze_order | Insight freeze order | Controls if we want to compute freeze order change insights |

| insight_no_work_shifts | No work insights horizont | Horizont in number of shifts for which we compute no-work insights for lines in the plant |

| make_to_order | Make to order production strategy | If true indicates that the plant is using make to order production strategy |

| microplan_show_setup_code | Show setup code on microplan | Indicates if material’s setup code should be displayed in work-orders table on microplan |

| norm_fallback_threshold_h | Normative-fallback threshold for duration | Threshold for duration below which the duration falls back to normative |

| plan_import_convert_operation_units | Plan import: convert operation measurement untis | Convert operation unit of measure to plan unit of measure. Modifies normative values according to alternative unites and conversion factors form SAP. (default false) |

| plan_import_delivered_quantities | Plan import: retrieve delivered quantites | Plan import will retrieve quantites delivered for each active order of the given plant. These quantities will need dedicated stock locations to be visible. |

| plan_import_from_days | Plan import from how many days back | Indicate how many days is the starting date for importing plan. (will be discontinued). Default:0 |

| plan_import_operation_output_stock_keys | Plan import: operation output stock keys | Comma separated list of operation output stock keys used for deciding if an operation outputs to stock. Used when importing plan. |

| plan_import_output_stock_postprocess | Plan import: operation output stock post-processing | Type of post-processing output stock flag when importing plan.Value nop means no postprocessing. Value external_resolved: uses output_stock that comes through import, but will only consider the last flagged operation as stock output, to ensure that exactly one operation has output stock true for each work order. Value rules: ignores external output_stock and determines which operation outputs to stock based on plant and line settings.(Default external_resolved) |

| plan_import_planned_orders | Import planned orders | Flag for importing planned orders for the plant |

| plan_import_scheduled_statuses | Plan import: scheduled status of operations | Plan import will retrieve scheduled statuses for all imported operations. If false, all operations will be scheduled in LEAP. If true, the status will depend on the plan_import_scheduled_statuses_skip_sim, which can be set for each line group separately. |

| plan_sap_lang | Plan import language | Indicates language for SAP plan data import |

| planning_table_parallel | Parallel orders on planning table | Show parallel orders on planning table |

| planning_table_production_versions | Use production versions on planning table | Use production versions on planning table |

| planning_table_save_report | Save full report on planning table | Add option to save full simulation report on planning table |

| planning_table_save_to_leap_mode | Which data can be saved to server from planning table | Which data can be saved to server from planning table |

| shift_board_support_12h_shifts | Supports 12h shifts | not in use |

| show_barcode | Show ID order barcode | Show ID order barcode in order modal dialog |

| sim_ignore_earliest_start | 24/7 mode | Set sim_ignore_earliest_start (24/7) for orders in the plant. Will affect only new orders at future imports. |

| skip_too_optimistic_fallback_to_normative | Skip fallback to normative in cases when model seems too optimistic | Skip fallback to normative in cases when model seems too optimistic |

| stock_forecast_consumed_received_scenario | Stock forecast: input materials delivery | Show input materials delivery child element in Stock forecast view |

| stock_forecast_consumed_scenario | Stock forecast: input materials | Show input materials child element in Stock forecast view |

| stock_forecast_produced_required_scenario | Stock forecast: output materials requirements | Show output materials requirements child element in Stock forecast view |

| stock_forecast_produced_scenario | Stock forecast: output materials | Show output materials child element in Stock forecast view |

| stock_requirements_import_types | Stock requirements import types | Define MRP elements/types of stock requirements to import for the plant |

| *tools_stock_location | Tools stock location | Sets stock location for tools in the plant |

| week_start_shift_offset | Start shift week offset | The week starts earlier than Monday first shift. This affects the alerts for too many assigned shifts per worker, copying previous week’s schedule etc. |

| work_schedule_preferred_shifts | Work schedule preferred shifts | Controls mapping from workday hours to enabled shifts. E.g. if a SAP capacity has 16 hours per day available, LEAP will assume that two whole shifts are enabled and one is closed. This setting defines which two shifts have priority to be open, the last one will remain closed. Once a user changes the default shifts, they will no longer be updated from SAP. |

| work_schedule_sunday_logic | Work schedule sunday logic | Controls swapping Friday last shift with Sunday last shift. Orders which are planned for Friday shift 3 will be scheduled on Sunday shift 3 in LEAP. |

Line-groups

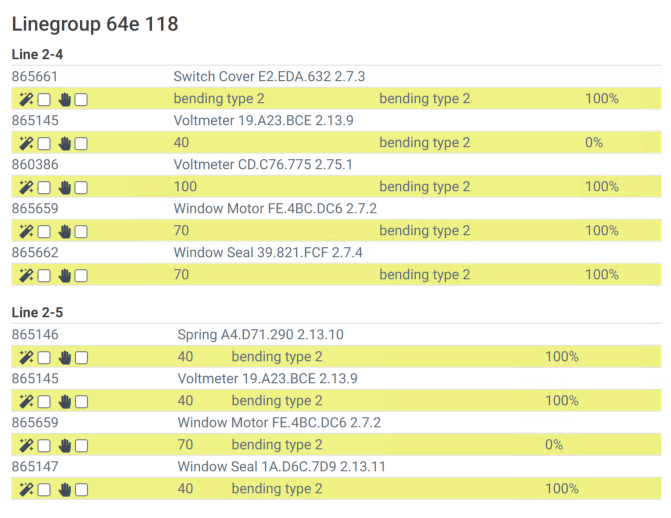

Matrix

Matrix view is a list of materials and operations, which can be executed on individual production lines of selected line group. The data is collected from two sources:

- Alternative production versions of material, if available

- Historical production data

For each line, a list of observed operations is show, together with percentage of productions on a particular line. Individual Line/Material combination can be enabled or disabled by setting the “magic wand” checkbox. Once disabled, automatic planning will not consider this line as a possible solution for this operation.

| automatic_scheduling | Automatic scheduling | If false, only manual scheduling will be possible. |

|

| batch_op | Batch op | Flag indicating that this line-group represents batch operations, e.g. aging furnaces. This setting will affect available views for this line-group. | |

| copy_week_strategy | Week-copying strategy | Strategy for copying shift assignments from previous week, for all lines in this linegroup. | |

| day_shift_assignment_format | Day shift assignment format | Parameter which defines what shifts are exported in the daily export of the shifts report. Option 123 means export selected day’s morning, afternoon and night shifts. 231 means export selected day’s afternoon and night shifts and the following day’s morning shift. |

|

| derived_stock_status_visible | Derived stock status visible | Flag indicating that this line-group will have an additional stocks view visible, named “Aged materials”. Aged materials are created in LEAP and are not visible in ERP, and provide an additional insight into stocks of material in different stages of ageing. See Stocks-Aged materials | |

| gannt | Gantt | If true, Gantt chart will be available for this line-group. |

|

| gantt_min_day_width | Gantt min day width | Optional parameter which defines minimal number of pixles one day should take in gantt chart. Default value is ‘40’. | |

| gantt_number_of_days | Gantt number of days | Optional parameter, which defines how many days are shown on the Gantt chart. Default value is ‘28’. | |

| gantt_past_weeks | Gantt past weeks | Optional parameter, which defines how many past weeks are shown on the Gantt chart. Default value is given by the simulation ‘1’. | |

| gantt_show_empty_lines | Show empty lines on Gantt chart | Indicates if empty lines should be shown on Gantt chart | |

| gantt_show_history | Gantt show history | Sets the default value of ‘Show history’ option in Gantt chart. Default value is true. |

|

| has_pool | Has pool | Parameter which indicates that this line-group uses pool for assigning workers to shifts. The workers will be scheduled to a Pool line’s shifts in the first step, and to individual lines in the second step. One Pool-type line has to be present in the Linegroup if pool mode is used. | |

| hide_in_navigation | Hide in navigation | If true, this line-group will be hidden from GUI navigation | |

| microplan | Microplan | If true, Microplan view will be available for this line-group. |

|

| microplan_gantt_number_of_days | Microplan gantt number of days | Optional parameter, which defines how many days are shown on the Gantt chart when showing a single production line. Default values is ‘28’. | |

| microplan_gantt_show_history | Microplan gantt show history | Optional parameter, which defines if the single production line Gantt chart in microplan view shows history. Default is true |

|

| microplan_recalc_on_save | Microplan recalc on save | Immediately run new full simulation in the background on plan changes in microplan. Default is false |

|

| microplan_refresh_minutes | Microplan refresh report every (minutes) | Refresh report on microplan page (in minutes) | |

| microplan_show_alternative_unit | Show alternative unit on microplan | Indicates if alternative unit should be shown on microplan | |

| microplan_show_order_table | Microplan show order table | Optional parameter, which defines if order table is shown in Microplan view. Default is true |

|

| microplan_show_order_table_expected_completion | Show expected completion in work orders table on microplan | Indicates if expected completion should be shown in work orders table on microplan (only if microplan_show_order_table_shifts is disabled) |

|

| microplan_show_order_table_expected_start | Show expected start in work orders table on microplan | Indicates if expected start should be shown in work orders table on microplan (only if microplan_show_order_table_shifts is disabled) |

|

| microplan_show_order_table_external_operation_id | Show external operation id in work orders table on microplan | Indicates if external operation id should be shown in work orders table on microplan | |

| microplan_show_order_table_material | Show material in work orders table on microplan | Indicates if material should be shown in work orders table on microplan | |

| microplan_show_order_table_material_comment | Show material comment in work orders table on microplan | Indicates if material comment should be shown in work orders table on microplan | |

| microplan_show_order_table_operation | Show operation in work orders table on microplan | Indicates if operation should be shown in work orders table on microplan | |

| microplan_show_order_table_operation_comment | Show operation comment in work orders table on microplan | Indicates if operation comment should be shown in work orders table on microplan | |

| microplan_show_order_table_order_id | Show order ID in work orders table on microplan | Indicates if order ID should be shown in work orders table on microplan | |

| microplan_show_order_table_quantity | Show quantity in work orders table on microplan | Indicates if quantity should be shown in work orders table on microplan | |

| microplan_show_order_table_shifts | Microplan show order shifts | Optional parameter, which defines if order table also shows details by individual shifts. Default is false |

|

| microplan_show_order_table_time_to_complete | Show time to complete in work orders table on microplan | Indicates if time to complete should be shown in work orders table on microplan | |

| microplan_show_order_table_unscheduled_orders | Show unscheduled orders in work orders table on microplan | Indicates if unscheduled orders should be shown in work orders table on microplan | |

| microplan_show_sap_dates | Microplan show sap dates | Show sap date columns in Microplan order list. Default is true |

|

| microplan_show_shift_table | Microplan show shift table | Optional parameter, which defines if shift table is shown in Microplan view. Default is true |

|

| microplan_stock_forecast_location | Microplan stock forecast location | Defines which storage locations are shown by default in modal windows (Input materials, Produced materials) in Microplan view. Values: ‘shopfloor’ or ‘plant’ | |

| microplan_weeks | Microplan weeks | Optional parameter, which defines which weeks are shown on the microplan week-table view. Default values is [-1,0,1,2] |

|

| no_worker_horizon_shifts | No worker horizon shifts | Parameter defines for how many shifts in the future the ‘No worker’ insight should be generated. It can take up to 10 minutes for the changes to be visible. | |

| plan_import_new_orders_skip_sim | Set skip_sim for new orders | If true, new orders will appear as unscheduled | |

| plan_import_scheduled_statuses_skip_sim | Set skip_sim based on externally scheduled statuses | Sets skip_sim flag for operations that are not schedulled in external system. If true, unscheduled operations will also be unscheduled in LEAP until they are scheduled in LEAP and saved to ERP. | |

| planning_beam_size | SYSTEM | ||

| planning_board | Planning board | If true, Microplan view will be available for this line-group. If automatic_scheduling is enabled, it is best to set this to false, so it does not to interfere. |

|

| planning_break_orders | Defines if orders can be broken into smaller chunks. | Can order be broken into smaller chunks during automatic planning. Default is false. | |

| planning_can_change_workorder_line | Can workorder change line | Allow automatic planning to change workorder line. Default is true | |

| planning_complete_materials_at_start | Complete input materials must be available at the start of the operation | Complete input materials must be available at the start of the operation (no overlapping). Default is true | |

| planning_exact_tolerance | Tolerance allowed when tracking materials exactly | Tolerance allowed when tracking materials exactly. Example, 90% tolerance equals value 0.9. Default is 1.0 (no tolerance). | |

| planning_initiator | Planning initiator | Who initiates automatic planning. ‘cron’: a background job is run 1x per hour. In this case, there is no need for a planning table and is best to not show it at all. ‘planning board’: run the automatic scheduling manually via magic wand button, where scheduling parameters can be set for each run. | |

| planning_meta_optimization | Meta-optimizations of enabled shifts to be followed in cron-initiated automatic scheduling. | Defines how shifts are automatically opened/closed during optimization. ‘Max resources’: open a maximum number of shifts that can be covered by available workers. If people knowledge is imporant, enable people first. ‘Min shifts’: Turn off as many shifts as possible without creating additional delays. Just-in-time logic is used, so orders will be scheduled as late as possible, which means there might be closed shifts between orders on the same line. ‘Stock’: takes existing calendar and checks if any stock is not necessary to produce, and closes shifts accordingly. | |

| planning_mode | Planning mode | Mode of automatic planning. ‘Lines first’: if the number of people available is not a problem, then production lines are scheduled first. ‘People first’: If there is plenty of capacities on production lines but not enough workers are available, then people are scheduled first. This will also take into account workers’ competences. Default is ‘lines_first’. | |

| planning_order_operations_overlap | Allow operations within the order to overlap | Allow operations within the order to overlap. Default is false | |

| planning_override_shifts | Override shifts | Overrides existing enabled shifts and closes those that are not needed. ‘0’ means enable shifts with at least one person scheduled to work. ‘1’,’2’,’3,’ and ‘4’ means the number of shifts to start with. Works with meta_optimization value ‘min_shifts’. |

|

| planning_ramp_up_factor | Ramp-up factor for planning | Ramp-up factor for planning - ‘warm-up’ penalty for the first 30 pieces. | |

| planning_setup_code_change_factor | Increase of penalty for material-change when setup-code is different. | Increase of penalty for material-change when setup-code is different. Specific for each use case. Default is 2. | |

| planning_smooth_needs | SYSTEM | ||

| planning_split_order_min_hours | Minimal length of chunks in hours. | Minimal length of chunks in hours. Default is 8. | |

| planning_table_horizon_days | Planning table horizon | Plan only orders with earliest start date up to ‘planning_table_horizon_days’ from now. | |

| planning_table_save_to_erp | Enable saving to ERP | Enable planning board save to erp button | |

| planning_table_save_to_erp_weeks | Number of weeks used for recalculating simulation when saving to ERP | Number of weeks used for recalculating simulation when saving to ERP | |

| planning_table_show_split_screen | Show split screen planning table | Show split screen planning table | |

| planning_table_unscheduled_move_days | Move unscheduled orders when saving | When saving to ERP, move unscheduled orders planning_table_unscheduled_move_days days from now. Default is 0 |

|

| planning_table_weeks | Planning table weeks | Number of weeks displayed on the planning board | |

| planning_time_horizont_buffer | Buffer that the time orders starting in time horizont need to finish | The time-horizon extra buffer to account for the time orders starting in time horizont need to finish. Should correspond to maximal order lenght. Default is 7. | |

| planning_time_horizont_needs | Extra days beyond time horizont for including needs in the planning process | The time-horizon extra days beyond time horizont for including needs in the planning process. Default is 7. | |

| planning_time_horizont_shifts | The time-horizon for planning. Default is 42. | The time-horizon for planning. Default is 42 (two weeks). | |

| planning_time_horizont_unit | Horizon unit for automatic scheduling on planning table | Choose unit for horizon on automatic scheduling on planning table | |

| planning_tool_setup_factor | Tool setup penalty factor | Tool setup penalty share in BFS score. This is multiplied with the tool setup criteria score. Default is 4. | |

| planning_track_customer_priorty | Should planning account for customer priortiy | Should planning account for customer priortiy. Default is false | |

| planning_track_input_material | Should input-materials be tracked during planning. | If true, input-materials availability will be taken into account during automatic planning, if planning_initiator is ‘chron’. Default is false. |

|

| planning_track_stock_levels | Should planning account for value of material on stock | Should planning account for value of material on stock. Default is false. | |

| planning_use_material_codes | Use material codes | Use material codes in planning to compute changover times. Default is false | |

| planning_time_horizont_shifts | The time-horizon for planning. Default is 42. | The time-horizon for planning. Default is 42 (two weeks). | |

| print_only_assigned_lines | Print only assigned lines | When printing the shift-board, print only lines with assigned worker(s) | |

| rotate_opposite_direction | Rotate opposite direction | Parameter defines direction of rotation when copying previous week in shift-board, when using shift_preference_rotate strategy. Option true means 321 shift rotation. Option false means 123 shift rotation. |

|

| shift_assignment_group_by_people | Shift assignment group by people | Parameter which groups the export of the daily schedule by people instead of grouping by lines | |

| shift_board | Shift board | If true, Shift-board view will be available for this line-group for scheduling workers. |

|

| stock_forecast | Stock forecast | Shows or hides “Stock forecast”, “Out of Stock” and “Requirement delays” views. Forecasting enables warehouses to keep track of sales and anticipated demand, so they can ensure that the available stock is adequate to meet customer needs. | |

| stock_forecast_shopfloor_option_default | Shop-floor only toggle default state | Default state of the shop-floor only toggle. Default is true |

|

| stock_forecast_show_safety_stock | Show safety stock | Show safety stock levels on stock forecast page. Default is false. |

|

| stock_forecast_show_shopfloor_option | Stock forecast show shopfloor option | If true, the checkbox “Include only shopfloor warehouses” will be shown to toggle between displaying either shopfloor only and overall inventory level on stock forecast page. Default is true |

|

| subcontracting | Subcontracting | Indicator that this line-group uses subcontracting. An additional view will be available in Plan tab. | |

| weekly_realization | Weekly realization | If true, Weekly realization view will be available for this line-group. |

|

| weekly_realization_downtimes_view | Weekly realizations downtimes view | Incidator to show downtimes in dropdown | |

| weekly_realization_scrap_view | Weekly realizations scrap view | Incidator to show scrap in dropdown | |

| weekly_realization_show_workers | Weekly realization show workers | Optional parameter, which defines if worker names are shown in the weekly realization view. Default value is ‘true’. | |

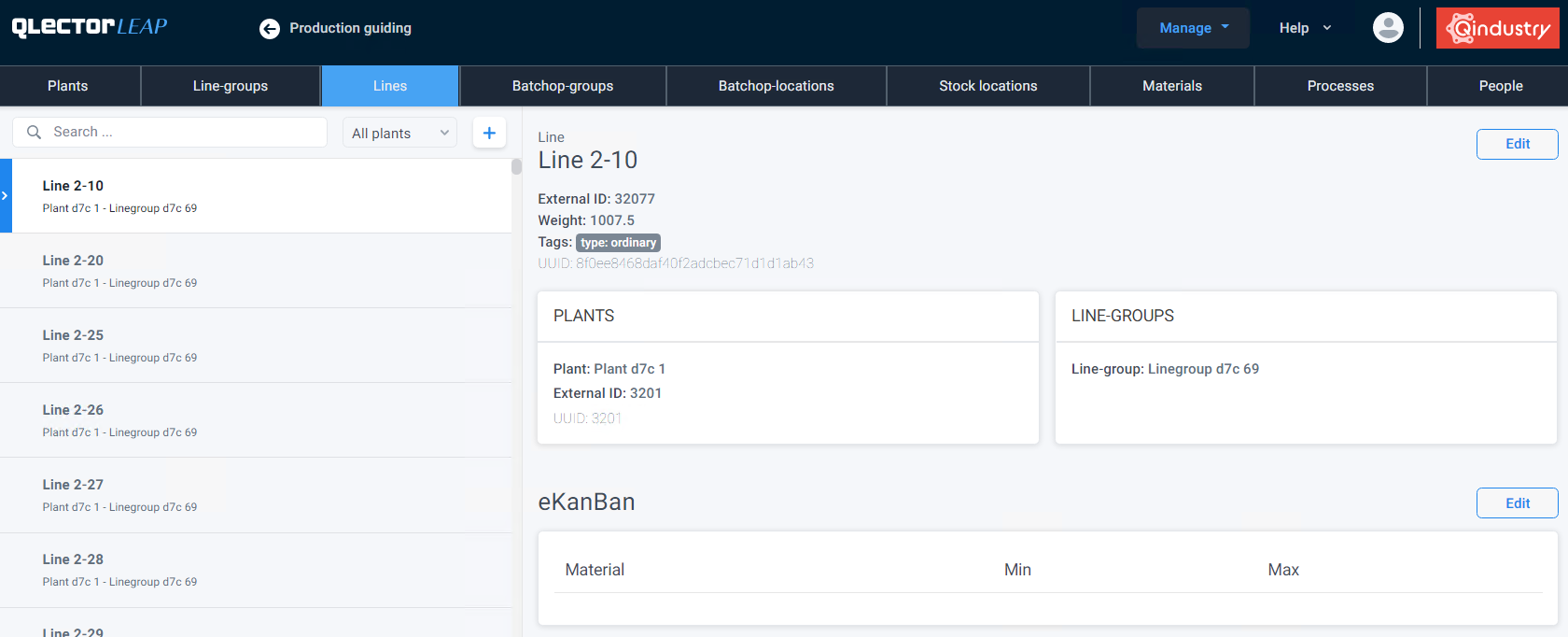

Lines

- Title: name of the line

- External ID: ID of the line in ERP

- Weight: order position in lists

Type

- Aging

- Asesembly

- Cameraman

- Control

- Line-group lead

- Non-work

- Ordinary

- Packaging

- Pool This line is used as a container for other lines when scheduling people in Pool mode. Other lines will be automatically included in this one, if their common Linegroup’s

has_pooltag is True. No more than one line per Linegroup should be defined as Pool. - Shift-lead

- Sick leave If you select this type, make sure to enable the

insights_skip_no_work_in_shifttag, so that unnecessary insights of this type will not be created. - Subcontraction

- Tool setup

| bottleneck | Bottleneck | Flag if this line is bottleneck. If false, automatic scheduling will not schedule this line. Note: if automatic scheduling is enabled for the parent Linegroup, the Line will only be visible on planning board if bottleneck= True. |

| calendar_line | 21 characters long numerical string, each number represents shift of the week | 21 characters long numerical string, each number represents shift of the week |

| capacity_factor | Capacity factor | How many work orders can be executed in parallel on the line. This parameters is used as constraint by automatic planning. When >1, simulation allows for parallel execution of work orders starting with time_start and regardles of capacity. Default is 1. |

| copy_week_strategy | Strategy for copying shift assignments | Strategy for copying shift assignments from previous week, for all lines in this linegroup. COPY;FOUR SHIFT ROTATION;SHIFT PREFERENCE ROTATE;SIMPLE ROTATE |

| ignore_prediction_model | Indicate that normatives are used for predictions | If true, predictions on this line will use normatives insted of historical data models |

| insights_skip_no_person | Skip ‘no_person’ insight this line. | Parameter that controls if insights of the type ‘no_person’ should be skipped for this line. Default is ‘false’. |

| insights_skip_no_shift | Skip ‘no_shift’ insight for this line. | Parameter that controls if insights of the type ‘no_shift’ should be skipped for this line. Default is ‘false’. |

| insights_skip_no_work_in_shift | Skip ‘no_work_in_shift’ insight for this line. | Parameter that controls if insights of the type ‘no_work_in_shift’ should be skipped for this line. Default is ‘false’. |

| insights_skip_plan_change | Skip plan changes insights this line. | Parameter that controls if insights of the types ‘plan_change_quantity’, ‘plan_change_shifts’, ‘plan_change_start’ and ‘plan_change_end’ should be skipped for this line. Default is ‘false’. |

| machine_external_id | External_id of machine if available | External_id of machine if available |

| overlapping_orders_line | Operations can overlap | If orders can overlap on this line. If ‘true’, automatic planning will use capacity_factor tag. Default is ‘false’. |

| multiple_machines_child | Multiple machine tag | Flag if this line is a child line based on its machine_external_id |

| multiple_machines_default_child | Multiple machines default child | external_id of default multiple machine child line |

| multiple_machines_parent | Multiple machines parent | Flag if this is a parent line, supporting multiple machine child lines |

| multiple_machines_parent_line_external_id | Multiple machines parent line external_id | external_id of multiple machine parent line |

| overlapping_orders_line | Operations can overlap | If orders can overlap on this line. If ‘true’, automatic planning will use capacity_factor tag. Default is ‘false’. |

| plan_import_output_stock | Plan import: output to stock | If true, operations on this line can output to stock. Default: true. |

| rotate_opposite_direction | Parameter defines the direction of the shift rotation | Parameter defines direction of rotation when copying previous week when using shift_preference_rotate strategy. Option true means 321 shift rotation. Option false means 123 shift rotation. |

| set_operation_time_start | Set operation time start | Enables setting time_start to operations on the line. |

| simulation_type | Simulation type | Type of simulation that is to be used for orders on this line. Default is ‘model’. |

| skip_autoclose_orders | Parameter that controls if orders can be automatically closed when productions reach toal order quantity. | Parameter that controls if orders can be automatically closed in LEAP when confirmed quantity reaches total order quantity. Default is ‘false’ and allows such automatic closing. |

| skip_planning | Skip planning | If true, planning will be skipped for this line. |

| skip_shift_board | Skip shift board | If true, this line will not appear in Shift-board view. |

| skip_stock_analysis | Skip stock analysis | If true, stock analysis will be skipped for line |

| skip_weekly_realization | Skip weekly realization | If true, this line will be excluded from weekly realization |

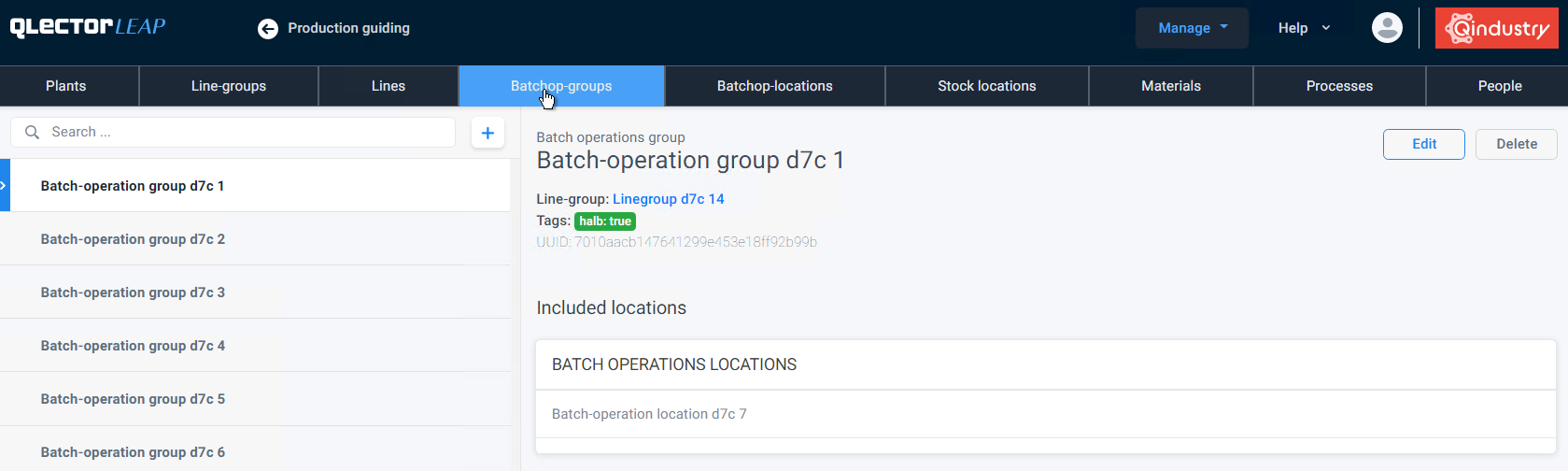

Batchop-groups

Batch operation groups are special type of line groups. An existing line group can be defined as a batch operation group.

Batchop-locations

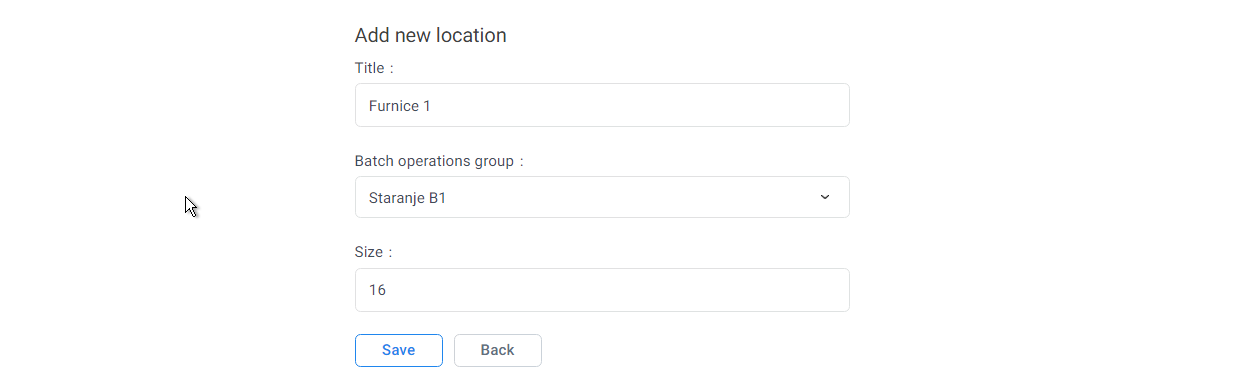

Batch operation locations are processing units, which take material from multiple orders and process them in a batch. They can be real machines (e.g. furnice) or virtual capacities (serving only as a way of tracking progress, e.g. air drying)

To create a new batchop location, click on the + icon in the left pane. Enter the location title, select which existing Batchop group it belongs to and define its capacity.

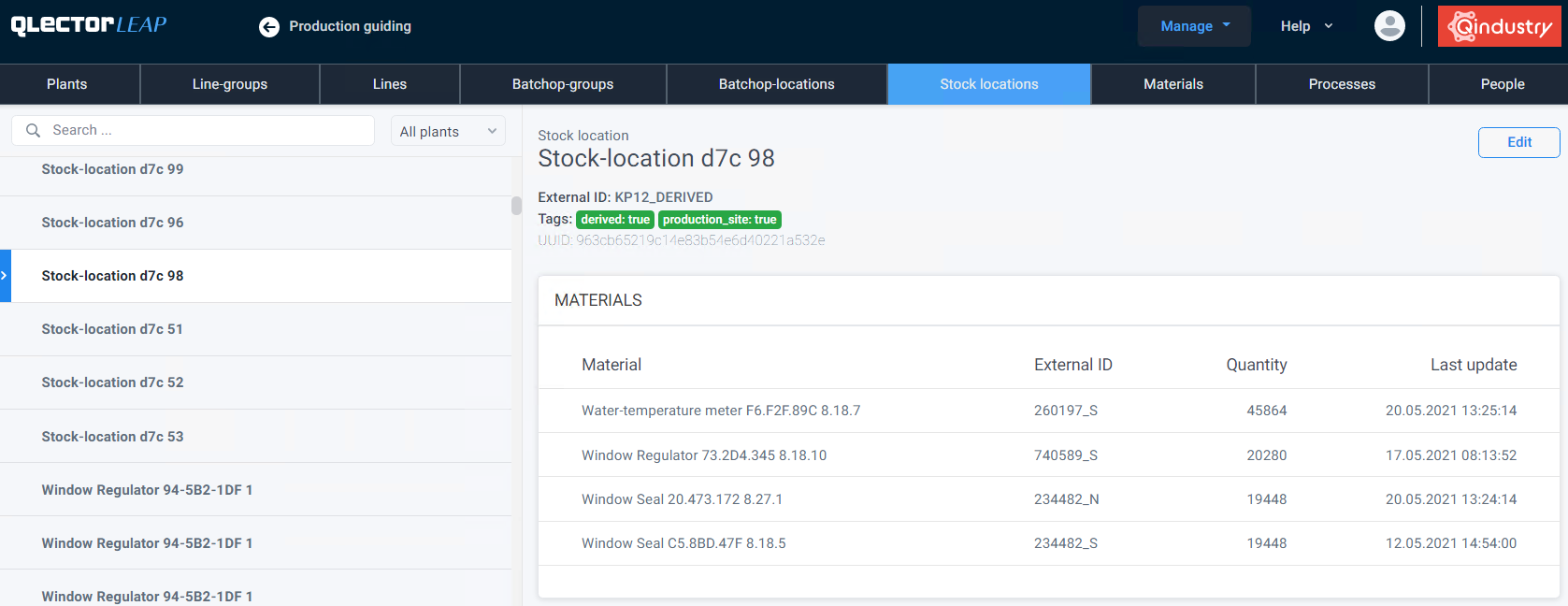

Stock locations

| affiliated_site | Affiliated site | Indicates that the storage location is a part of another plant, but the stock levels can be seen in this plant as well. |

| derived | SYSTEM | |

| production_site | Production site | Indicates that the storage location is available on the shopfloor. |

| safety_stock | SYSTEM | |

| storage_site | Storage site | Indicates that the storage location is not available on the shopfloor, but can be retrieved with some time cost when needed. This stock will not be taken into account if “show only shopfloor locations” is checked in stock views. If the plant does not differentiate production and storage locations, that checkbox can be hidden from GUI by setting stock_forecast_show_shopfloor_option for Line-group to False |

| withdrawal | SYSTEM | |

| work_orders | SYSTEM | |

| yield_not_delivered | SYSTEM | |

| *returns | Returned items storage location | If true indicates that the storage location is used for returned items. |

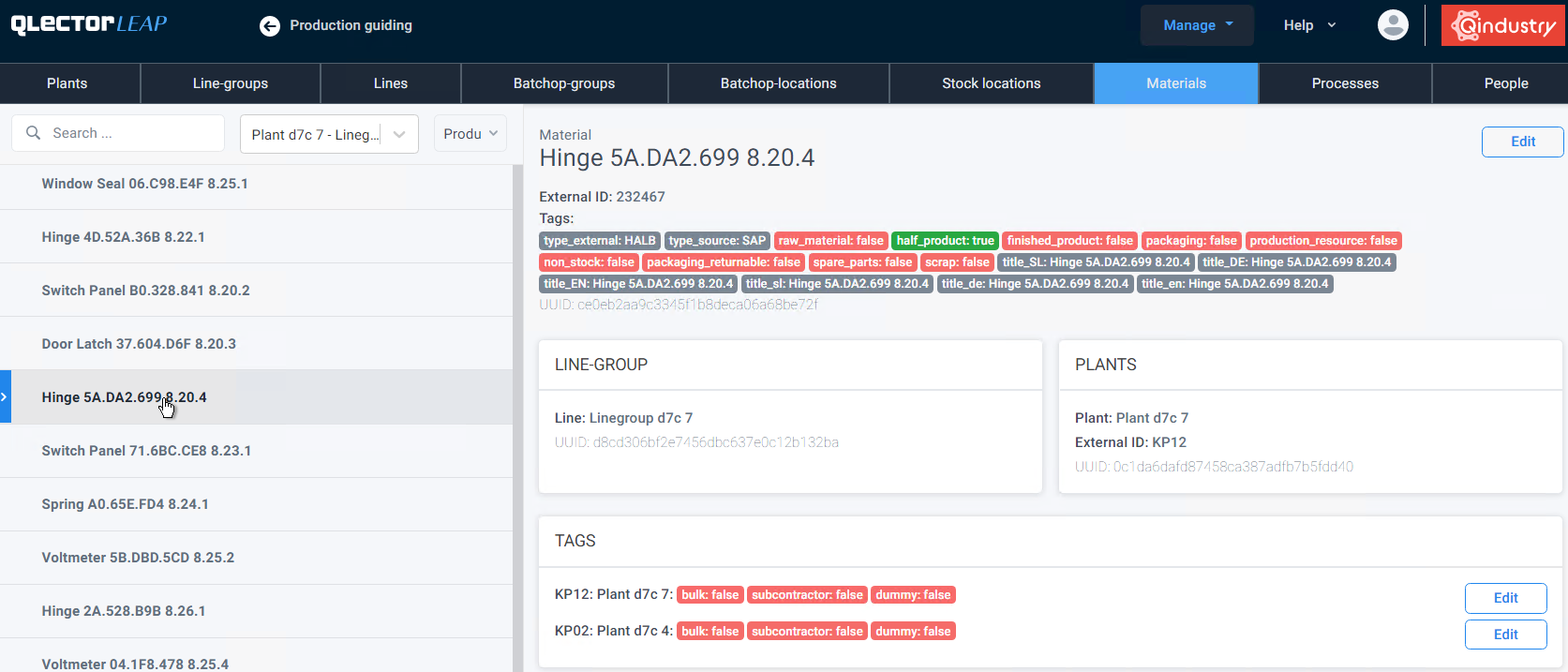

Materials

Materials are listed in the left pane. Plant and material type (produced/consumed) must be selected from respective drop-down menus.

When a material is selected, details are shown in the right pane:

| type_external | Type external | A string that encodes the external type code. By default the type is not known. This value is read from SAp and is not to be changed. | |

| type_source | Type source | A string that encodes the external source that defined the type code (SAP for example). By default the source is unknown. An example is ‘SAP’. Not to be changed. | |

| skip_stock_analysis | Skip stock anaylsis | Ignore this material when doing stock forecasting and alerting. Default is false |

|

| skip_planning | Skip planning | Ignore this material when scanning orders. Default is false |

|

| material_subcontracted | Material subcontracted | Indicates that this material is currently being produced by a subcontractor. Default is false. Currently unused. |

|

| complexity | Complexity | A string indicating material complexity. Works in combination with allowed_complexities tag in People settings to define which materials a person is able to manufacture. |

|

| setup_code | Setup code | Code indicating setup id for this material. Will be used by planning together with a switch-matrix to indicate complexity of switching between certain materials. | |

| *parallel | Parallel material | Flag indicating this material is meta-material placeholder for parallel materials. |

- Non-standard data

These tags are not meant to be changed!

- Edit material in selected Plant:

| material_subcontracted | Material subcontracted | Manual tag, indicating that subcontracting is supplying this material. Used for stock triggering. Default is false |

| material_subcontracting_lead_time | Material subcontracting lead time | Specify delivery time for chunk orders in hours. |

| bulk | Bulk | If true it indicates that the material is a bulk material. By default false. Not to be changed. |

| dummy | Dummy | If true it indicates that the material is a dummy (phantom) material. By default false. Not to be changed |

| subcontractor | Subcontractor | Automatic tag, indicating that subcontracting is supplying this material. Imported from SAP, used for stock triggering. By default false. |

| stock_requirements_import_include_types | Stock requirements import include types | Stock requirements import tags to include for the material |

| stock_requirements_import_exclude_types | Stock requirements import exclude types | Stock requirements import tags to exclude for the material |

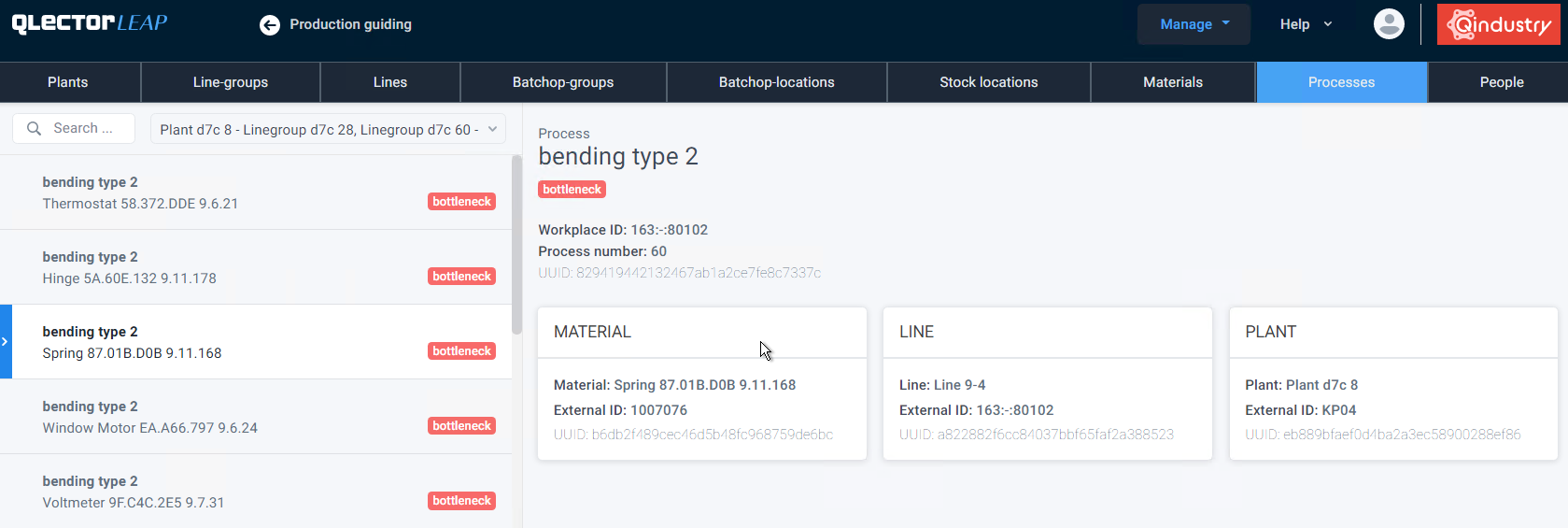

Processes

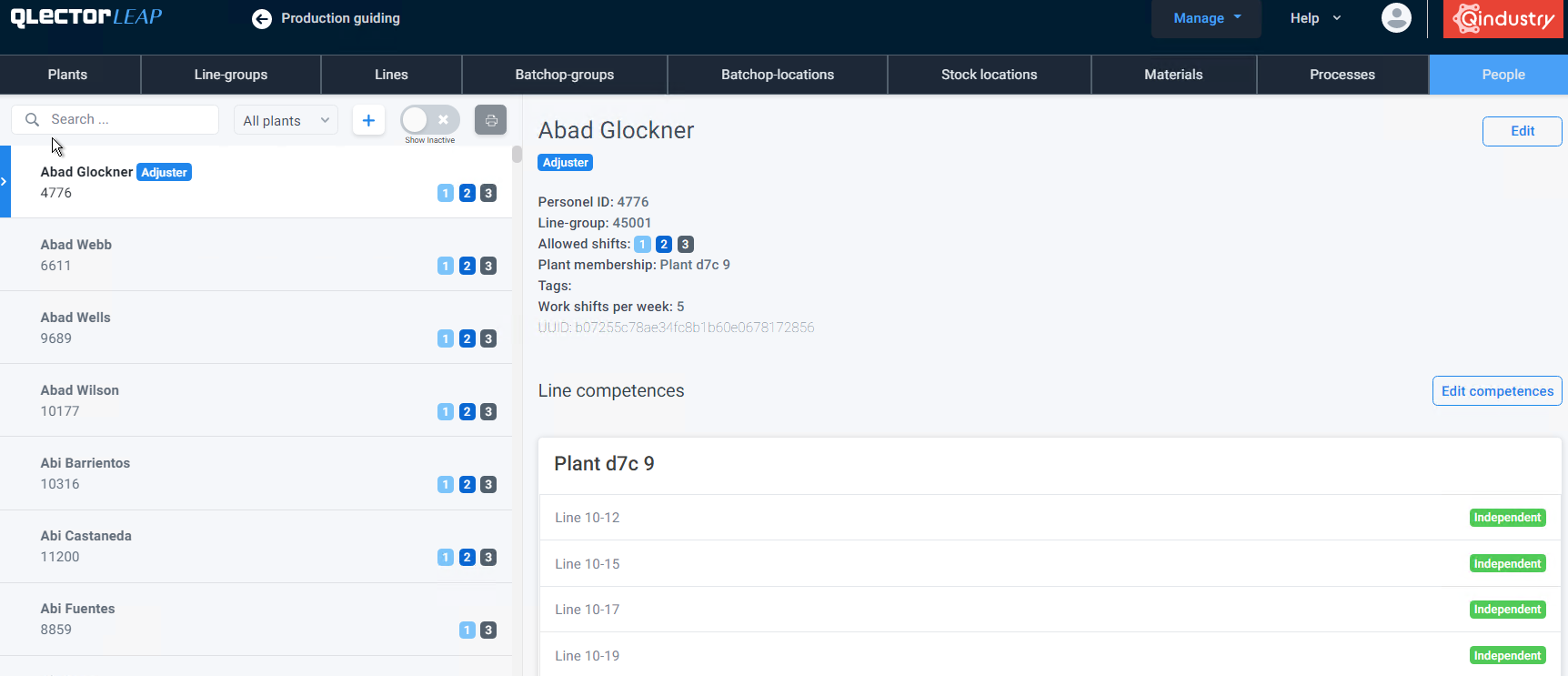

People

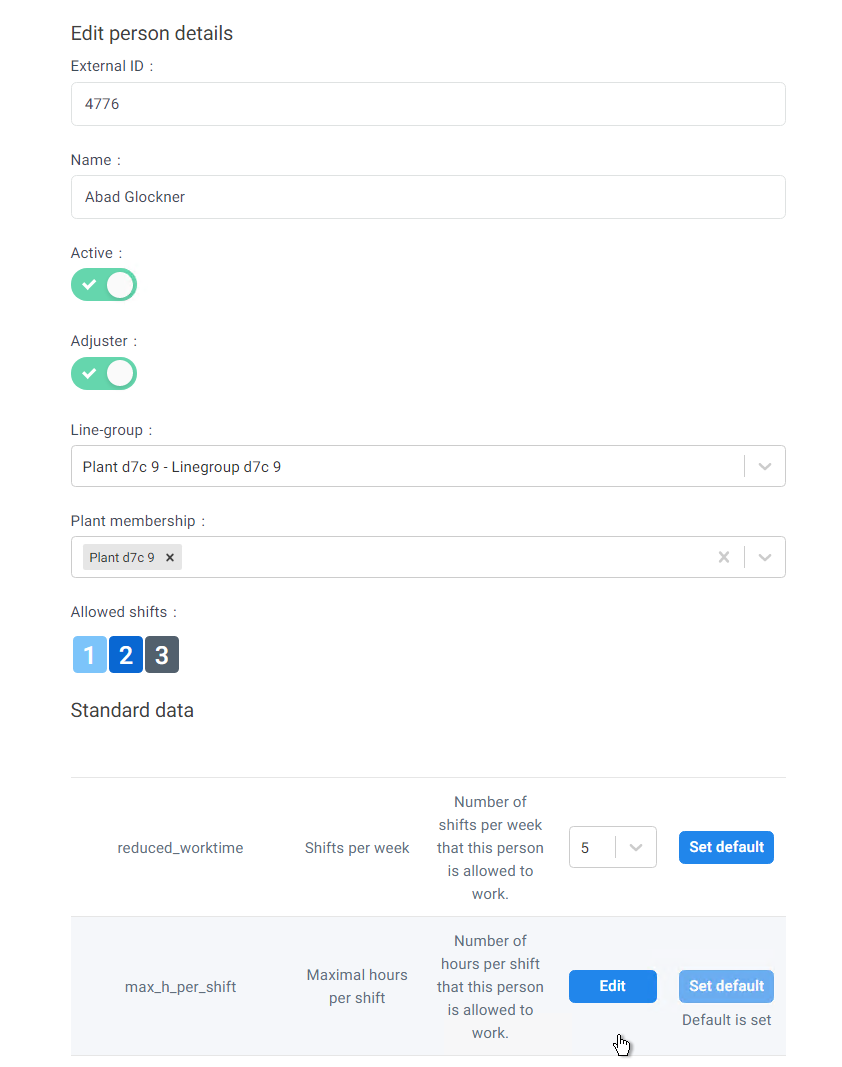

Workers can be added and edited here. An existing worker can be found via searchbox.

- Show Inactive: if a person with status Inactive is to be activated, the Show inactive must be selected first.

- External ID: ID of employee in ERP (e.g. SAP)

- Active: disabling the Active status will hide the employee from shiftboard.

- Adjuster: a tag will be shown in Shiftboard for this person to indicate that they are an Adjuster

- Line-group: define in which line-groups they will be shown to be scheduled

- Plant membership:

- Allowed shifts: click on shift number to toggle between allowed and not allowed

| reduced_worktime | Shifts per week | Number of shifts per week that this person is allowed to work. |

| max_h_per_shift | Maximal hours per shift | Number of hours per shift that this person is allowed to work. |

| allowed_complexities | Allowed complexities | List of complexities that are allowed for this person. Works in combination with complexity tag in Material settings. |

| shift_board_works_12h_shifts | Indicates that the person works 12h shifts | Indicates that the person is working 12h shifts. The worker will be highlited on the shift-board. |

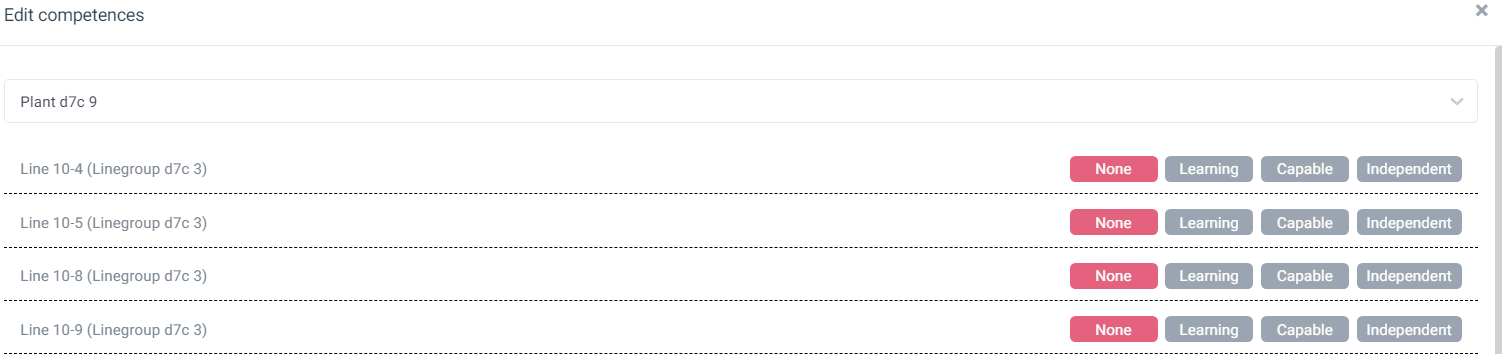

Edit competencies

Dashboards

Administrators only.

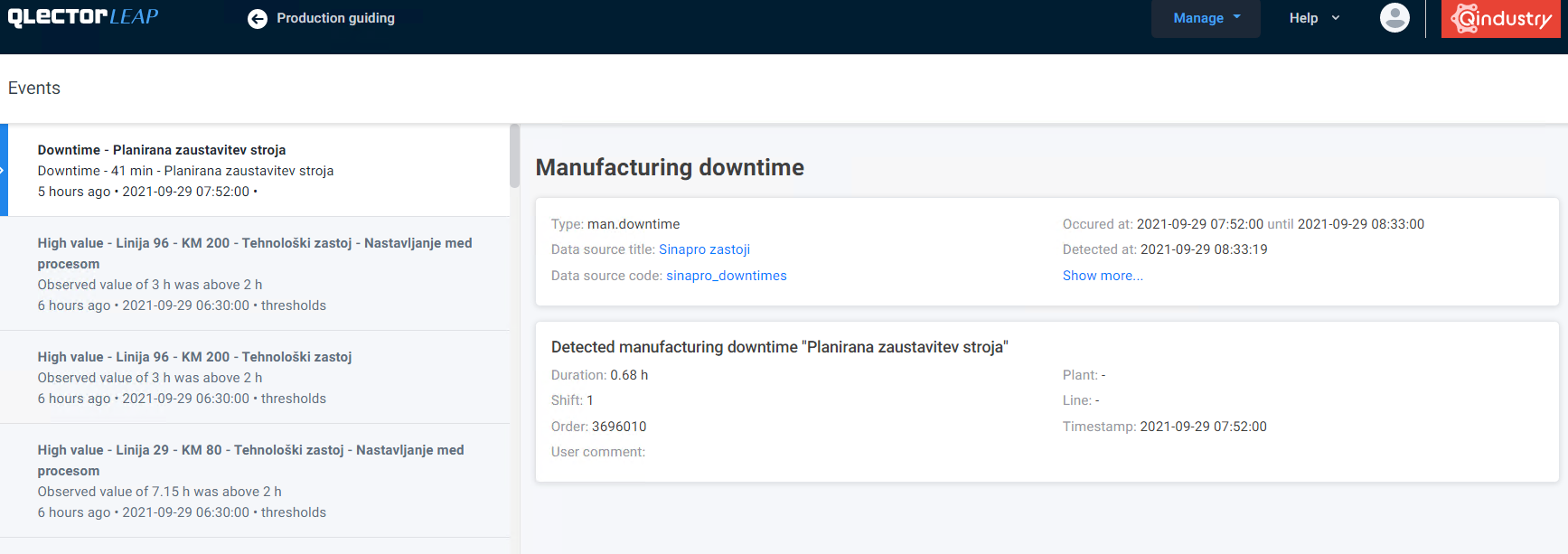

Events

Administrators only.

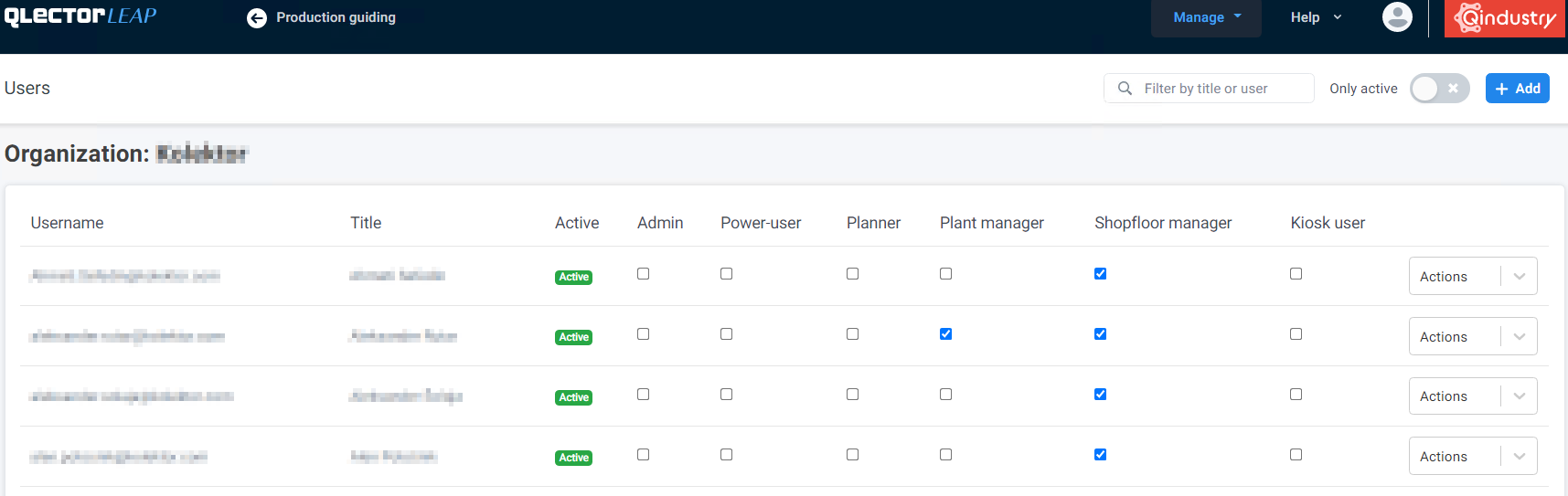

Users

Username Title Active Role Actions Impersonate Deactivate Line-groups Set PIN Set password Activate Reset password

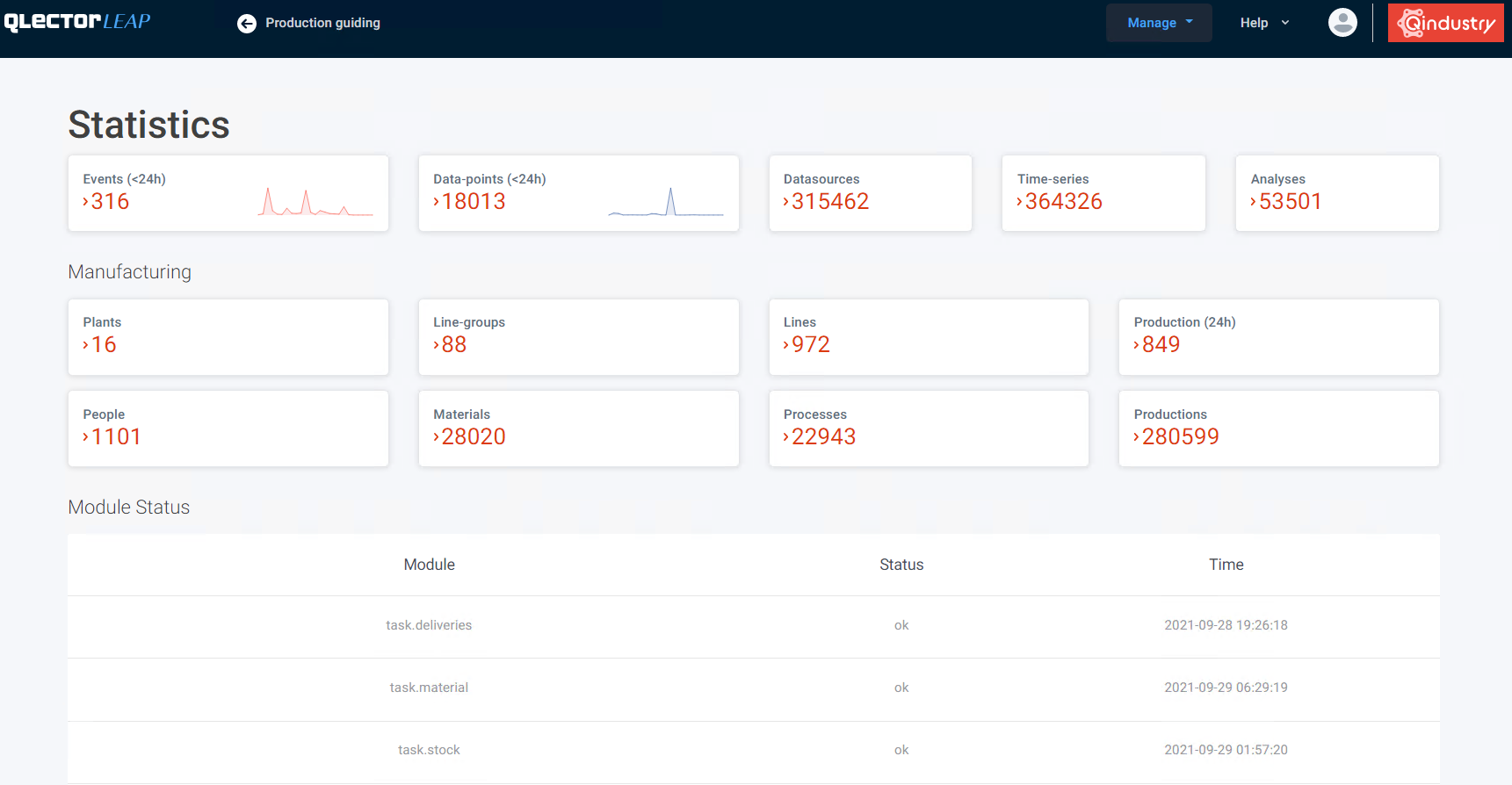

Statistics

Shows most recent data updates.

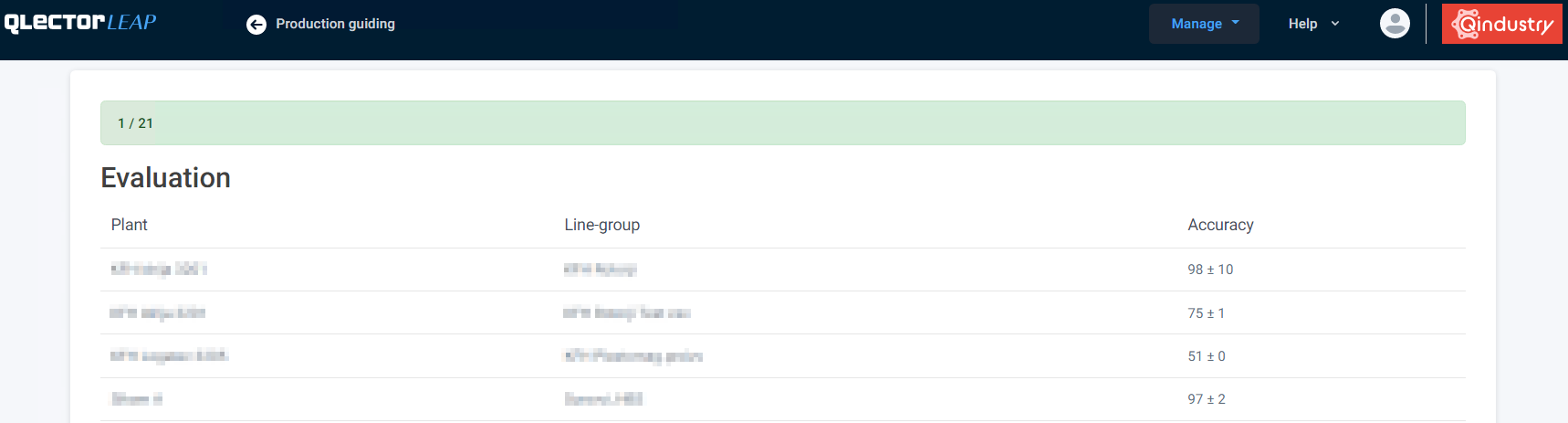

Evaluation

Shows evaluation of LEAP output forecast versus actual production output. Actual output is compared to LEAP data as they were 24 hours before the observed shift.

Manufacturing settings

Administrators only.

Custom files

Administrators only

Creating child production lines

When there are multiple machines for one SAP workcenter, we can create child lines to fetch production data, assign workers and schedule orders on individual machines rather then on one