Automatic planning in Qlector LEAP

Overview

Automatic planning in LEAP employs artificial intelligence methods of optimization. AI methods are based on data, so the whole of the data context needs to be considered when looking for an optimal solution. This includes all work and planned orders, call-offs and predicted stock levels of input materials. The user can decide what an optimal solution would look like by setting the relative weights to the criteria:

(1) minimize delays

(2) minimize tool changeover times

The user can also choose to track input materials or not. LEAP assigns relative weight to individual solutions (schedule) according to the current data context. When those weights are calculated, LEAP can choose the optimal plan. Verification of a solution can only be done with the same input data - the user can compare different solutions via the KPIs provided by LEAP.

Selecting production lines

Automatic planning will plan all lines in the line-group, unless we select only specific lines via the lines filter on the left. The non-selected lines will not be planned, but the input material, required by those lines, will still be accounted for in predicting the stock levels of input materials for the selected lines.

Scheduling operations to alternative lines

Scheduling can change the workcenter of an operation.It depends on the following settings:

The Plant-level setting planning_table_production_versions defines whether production versions or historical data should be used for changing a workcenter. Production versions are automatically transferred from SAP. Historical data can be edited in “Matrix” option in Line-group settings.

Line-group level setting planning_can_change_workorder_line defines whether planning can change a workcenter on production orders. If this is set to false, workcenters can only be changed on planned orders.

If production versions are enabled (plant-level setting: planning_table_production_versions), the following constraints need to be considered:

- In Production orders, production version can only be changed if BOM and structure of operations are the same.

- In Planned orders, production version can only be changed if BOM is the same.

- Production version change can not be saved to SAP, if the order is already partially confirmed. In this case, the changed workcenters are saved to SAP, but production version stays the same.

- Workcenter alternatives that are based on productions history are visible in the matrix, but can not be used if production versions are enabled.

Unscheduled operations

Orders that could not be scheduled due to various reasons (missing input material, capacity overload…) will be moved to unscheduled pool. The reason for this move will be stated in the scheduling explanation (see below).

Frozen operations

Individual operations can be set as frozen via control+click menu. Automatic scheduling prioritises these operations, so they are scheduled to finish on same time as they were frozen.

Scheduling explanation

After automatic planning, explanations are be available for each order on the left. If an operation was not a part of planning, that is also stated.

Special settings for manual start of automatic planning

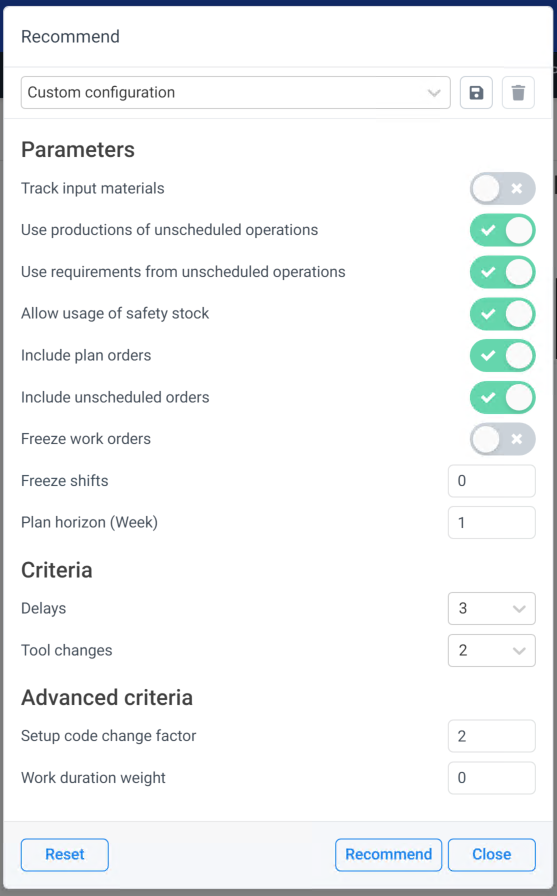

When we choose automatic planning via the magic wand button, a window with additional settings will be displayed. These settings will be saved until the browser is closed or refreshed.

Track input materials

Only operations, which are covered with input materials, will be scheduled.

The stock level of input material is defined by stock forecasting, which takes into account:

- Current stock level in the warehouse (accounting for any safety stock)

- Planned call-offs and deliveries on respective dates

- Forecast of input material production on line that are not part of currently selected Line-group.

- Forecast of consuption on lines that are not part of currently selected Line-group.

Input material will be assigned to operations in the same sequence as they start. Operation that starts first will be assigned all of its required quantity. If there is not enough material left to cover the next operation, the material will not be split between the two operations. Instead, the second operation will either not be scheduled or scheduled later, when the input material will be available again.

LEAP supports two modes of checking material availability via the Line-group setting planning_complete_materials_at_start.

If this setting is true, the operation can only be scheduled so that all required material is available at the start of the operation.

If it is false, the operation can be scheduled earlier, providing that the missing quantity will be made available during the production (either through delivery or in-house production).

Linegroup setting planning_exact_tolerance defines the tolerance of input material quantity. Default is 1, meaning a 100% of required input material must be available to schedule the operation. If this value is lower, the operation will be scheduled despite an input material shortage. E.g. a value of 0.95 will allow an operation to be scheduled even if it is missing up to 5% of the required input material.

When we are scheduling an operation for a semi-product and the operation that consumes that semi-product, LEAP will account for a time buffer: how many hours after the semi-product is posted to stock can the next order start to consume it. This time buffer is calculated from historical data.

Accounting for input material can produce “holes” in schedule: periods with no operation, if no operation can be scheduled at that time.

If input material is not available in selected planning horizon, operation will be pushed back, behind the scheduled operation.

If we have selected only specific lines inside the current line-group, then we have two possible scenarios, regarding this setting:

Scenario 1: Track input material

- Material, which is consumed on both selected and non-selected lines, will cover the non-selected lines first. In case there is not enough material left for operations on selected lines, these operations will be pushed back, or moved to unscheduled, if no solution can be found.

Scenario 2: DO NOT track input material

- Operation on selected lines will be scheduled without regard of input material. Consequently, they can be scheduled so early that they take material from orders on non-selectd lines.

Allow usage of safety stock

If this option is enabled, all input material stock, including safety stock, will be regarded as available for consumption. In cases, where material shortage results in delays or empty capacities, enabling this option may alleviate the problem.

Include plan orders

If planned orders are included, their operations will also be scheduled. If not, they will be moved to unscheduled pool. Planned order operations workcenter can be automatically changed by changing the production version.

Include unscheduled orders

Schedule operations, which are currently unscheduled. If this is disabled, unscheduled operations will not be scheduled.

Freeze work orders

If work orders operations are frozen, they will keep their sequence and only planned order operation will be scheduled. If this setting is set, and planned orders are not included, then nothing will be scheduled.

Freeze shifts

If we wish to preserve the current schedule in a certain period from current shift, we can freeze the shifts. We can set the following values: -1 schedule also orders that are already being produced 0 schedule only operations that have not yet started 1 schedule only operations that, according to current schedule, start after the first shift 2 schedule only operations that, according to current schedule, start after the second shift …

Plan horizon

This parameter sets the time frame in which the automatic planning will be done. The value represents the number of weeks from the current date, where one week is 7 days.

Operations can only be scheduled on available capacities inside the plan horizon. An operation must start inside this horizon but can extend past the end of horizon, provided it ends the defined number of days after the end of horizon. This number is set in the line-group setting planning_time_horizont_buffer, default value being 7 days.

Planning includes all operation, present on the planning table (not only those displayed in the table horizon) and according to all other settings.

Deliveries of input material, call-offs, production and consumption in other line-groups are considered within the horizon, with an option to extend that time frame. This is set by the line-group setting planning_time_horizont_needs. Default value is 7 days, which means that scheduling will also consider call-offs that occur up to 7 days after the planning horizon. Thus, orders can cause delays in a shorter horizon because it did not consider a call-off that was outside the horizon.

Planning criteria

The weights (delays and tool changes) instruct the automatic planning, how important one criterion is in relation to the other. If both criteria are 5, they have the same effect as when both are 0.

Rectify

The option “Rectify” is used to maintain a proper order and overlapping of operations. Rectify keeps the current order of operations, they can only be moved to a later date to satisfy any mandatory overlapping demands. Input materials are also considered. It is therefore possible that operations will become unscheduled, if there is not enough input materials for them.

Analyzing results of automatic planning

After an automatic planning run, each operation on the Orders list on the left will have an explanation of the planning decision. These include:

-

Missing input material to schedule order

-

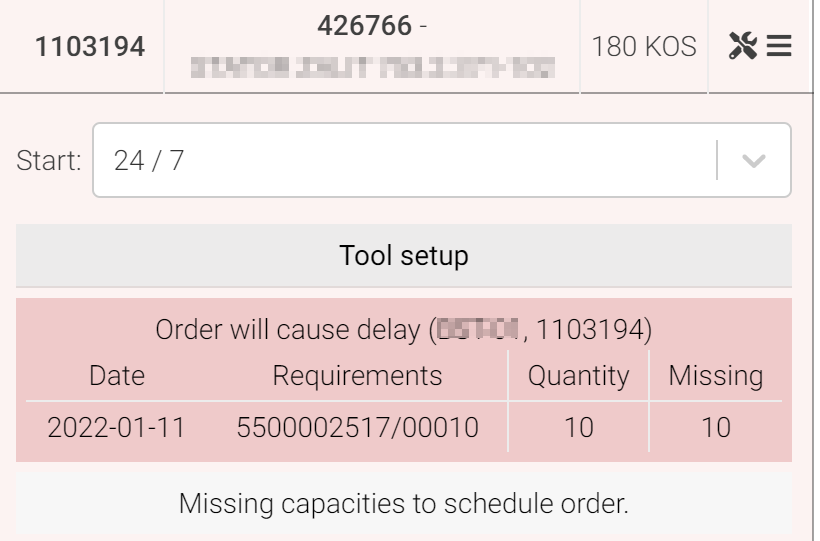

Missing capacities to schedule order Possible solutions: Extend the planning horizon (automatic planning parameter) Extend the planning horizon buffer, if orders are too long to finish inside the planning horizon (a Line group setting planning_time_horizont_buffer) Enable additional shifts

-

Order not scheduled due to earlier orders for the same material not being scheduled If there is more than one production order for the same material, automatic planning will not schedule a later order, if the earlier one could not be scheduled

-

Order not scheduled due to late exectuion of previous operation

-

Order was frozen and not moved by automatic scheduling Possible solution: Shorten Freeze shifts horizon. Disable Freeze production orders, if this is a production oder

-

Order not part of scheduling Possible solutions: Enable scheduling of planned orders, if this is a planned order

The schedule as a whole can be evaluated in the KPIs view. Also, a new stock forecast is available for assessment.